Manufacturing Process

Each piece of INCEPTA jewelry is crafted with precision and dedication. From the selection of ethically sourced diamonds to the final polish, our artisans combine modern technology with traditional techniques. Every step, from designing to casting, ensures that your jewelry meets the highest standards of quality and craftsmanship, resulting in timeless pieces that are built to last.

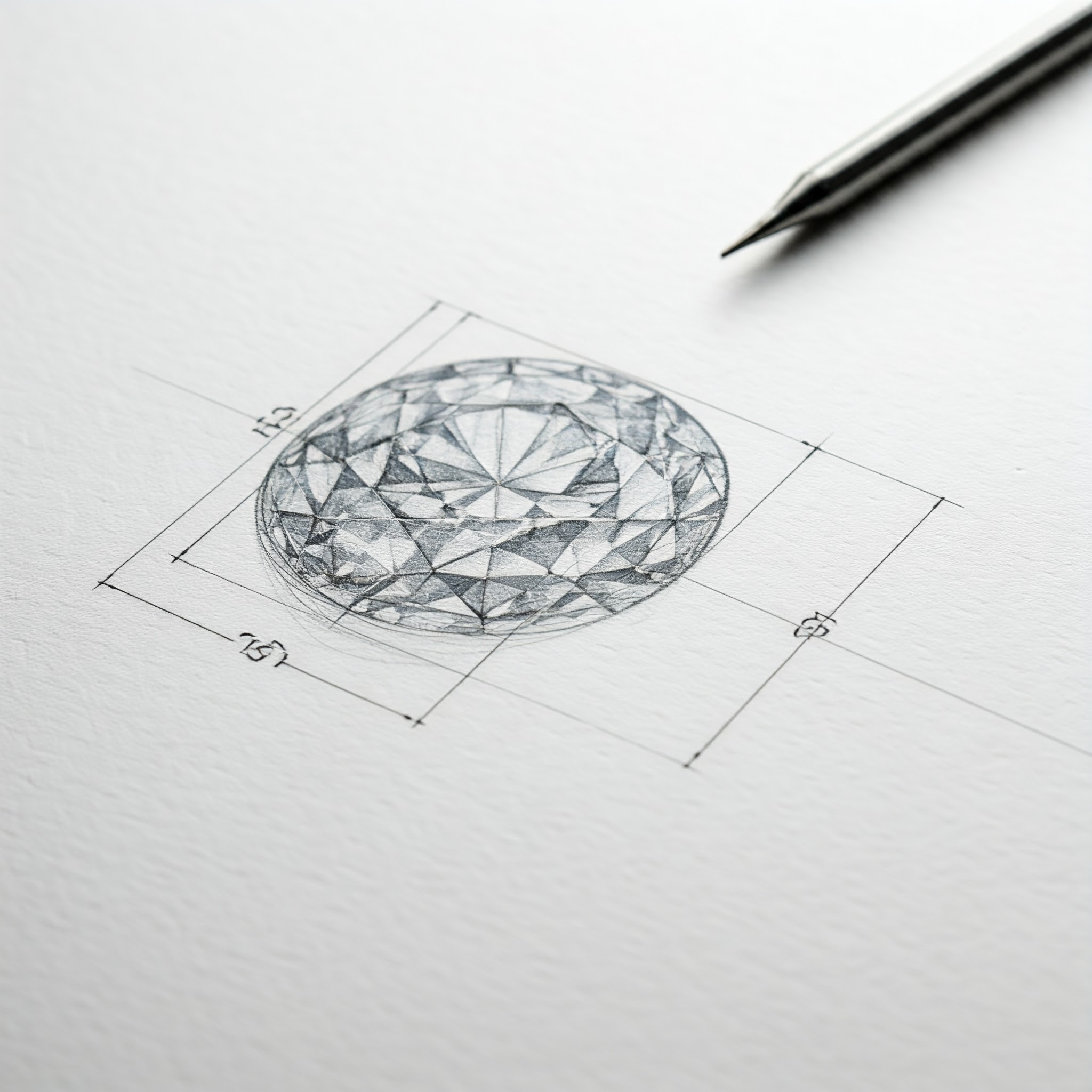

Design Development

At INCEPTA, we use advanced computer programs to design customized jewelry pieces just for you. Our designers create digital models to show you exactly how your jewelry will look before it's made

3D Wax Printing

For special pieces, we use high-tech 3-D printers to make precise wax models. These printers are so accurate, they can print details to the nearest 1/100th of a millimeter. Whether it's rings, pendants, or earrings, we can make it happen with amazing detail.

Casting Process

Once the wax models are perfect, we make molds for casting. We carefully place the wax models on special trees based on their size and weight. Then, we pour a special solution into the mold to create the jewelry.

Sizing, Setting, And Polishing

After the jewelry is made, we clean it up and send it to be stamped with a hallmark. This stamp shows that the metal is high quality. It's like a seal of approval for your jewelry.

Quality Assurance, Cleaning & Hallmarking

Our skilled jewelers set the diamonds and gems into your jewelry just the way you want. They make sure everything fits perfectly and looks amazing. Then, they polish it up so it shines bright.

Experience The INCEPTA Difference

We take care to package your jewelry beautifully. Each piece comes in a soft velvet bag to keep it safe. We try to use as little plastic as possible and use eco-friendly shipping methods to make sure your jewelry arrives safely.